Services

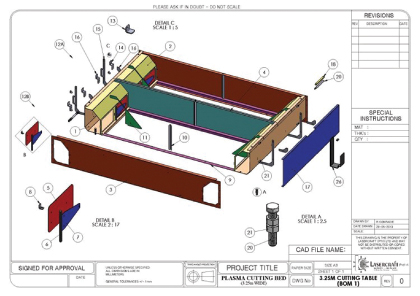

Design

Lasercraft uses Solidworks and various other CAD packages to perform all our design work.

Finished products can be done, from concept to completed product, quickly and efficiently using these design tools.

Cut

Laser

Laser cutting provides a precise method of cutting steel, involving a focused beam of laser light that melts, burns or vaporises metals, thus achieving accurate cuts with a quality finish. Lasercraft owns a number of state-of-the-art laser cutting machines to cater for bulk and custom designs.

Our quality laser cutting machines deliver:

- High accuracy

- Clean cutting

- Economical material usage

- Minimal distortion

- Swift setup

Depending on your specific requirements, Lasercraft can coordinate your complex laser cutting needs.

Cut

Tube laser

Our tube laser cutting machine can cut long pieces (up to 3,000mm x 65mm diameter) of tube or cut holes into sections of tube with incredible precision.

Cut

Water jet

Water jet cutting offers a cost-effective alternative to other cutting methods where tight tolerances are required. Water jet cutting is useful to cut parts that fall beyond the scope of laser cutting. The process uses cold water, leading therefore to no distortion, no heat input and no change to the mechanical properties of the material.

We can handle almost all materials, i.e. aluminium, copper, composites, armoured steel, glass, fibreglass, carbon fibre up to 100mm thick.

Cut

High definition (HD) plasma

Our state-of-the-art high definition plasma cutter (MesserHD plasma machine fitted with 400 Amp Hypertherm power source) can cut up to 80mm sheet metal in a large 3m by 40m bed, providing us with the capability to accurately cut very large sheets of aluminium and stainless steel.

Cut

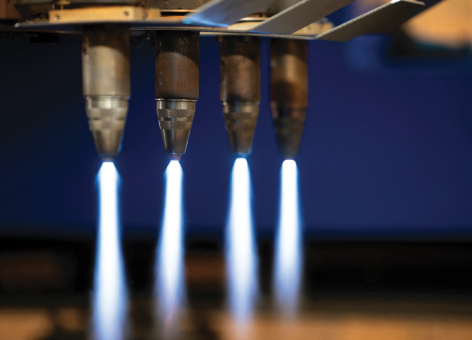

Oxy-fuel

Lasercraft s Messer oxy-fuel machine fitted with a four x cutting head allows us to cut extremely thick metals with ease. This cutting method, which uses a high velocity cutting torch of oxygen and fuel, makes it possible to produce almost any shape from carbon steel plates up to 200mm thick. The cutting area measures 3m by 6m.

Weld

Our welding department consists of 10 welding bays equipped with MIG/TIG welding machines to achieve the best possible manual welding results in mild and stainless steel. Spot welding machines and stud welding equipment add to all possible variations of permanent joining procedures.

Lasercraft also has three welding robots in operation. These welders allow us to greatly improve the overall quality and mass production with controlled technology.

Within our finishing department, all finished items are de-burred and polished, either by hand or by machine.

Machine & Fabricate

Lasercraft has a machining and fabrication department with the main objective to deliver quality prototypes and custom precision machined parts according to our customer’s specifications.

Our CNC machining department has six CNC milling machines that can handle a maximum capacity from 800mm x 400mm x 400mm up to 2,550mm x 1,000mm x 680mm with a load capacity of 2.5 tons.

Our turning department has three CNC lathes with a capacity of 300mm OD x 1000mm long and with an automatic bar feeder up to 35mm.

Press

Pressing offers flexible manufacturing runs without high capital expenditure, using dies and forming presses. High volumes are not required to justify the use of this equipment.

The process is very flexible in being able to produce many different configurations of parts due to the modular nature of the tooling employed. Lasercraft has two 100-ton presses and together with new technologies and our wide range of tooling this allows most complex part configurations to be produced in the most economical way possible.

Bend

Our clients benefit from the latest in bending technology, which uses CNC controlled back gauges and optical sensors to provide the finest precision, significantly reducing the rejection rate.

We can facilitate the bending of products like channels for truck chassis, small to large cones, square to rounds and transitions.

Lasercraft has the latest European-made hydraulic brake press, designed to deliver unrivaled results. Built with sophisticated software and an in-process angle management system, each piece of sheet metal is consistently formed to specific angles. We work with steel plate thicknesses from 0.5mm to 100mm and process metals from mild steel through to stainless steels and wear plates.

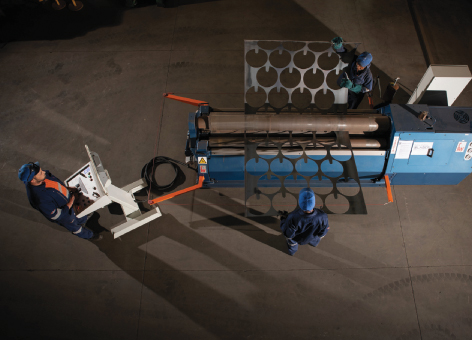

Roll

Our CNC rolling facility consists of one Faccin 4 roller (top roll) which enables us to roll metal up to 2,500mm long and 270mm diameter.

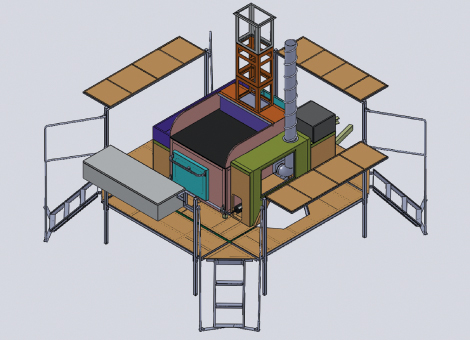

Assembly

Apart from producing the individual components to make up a part or item, Lasercraft can fit weld or insert any type of fasteners that are required in completed assemblies (e.g. weld nuts, weld studs, stand-offs, minarbs, press studs, etc).

Lasercraft has the skill and expertise to fully assemble, thus providing our clients with an all-round service from design to the final product.

DesignCutWeldmachine & fabricateBendRollASSEMBLY

LaserTube laserWater jetHigh definition (HD) plasmaOxy-fuel